Structural Light Steel Framing

Infill

Typical details

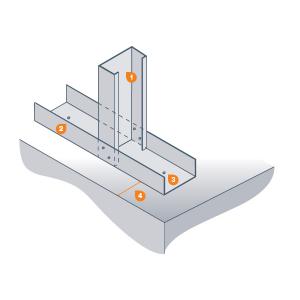

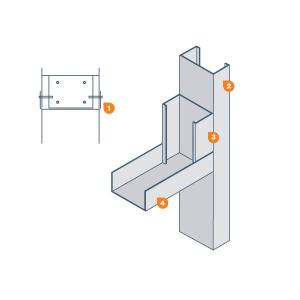

Screw Fixed Panel

- Stud

- Track

- Fix to concrete with Tapcon anchors at 600mm centres or nails at 200mm centres

- Refer to fixing guide for edge distances

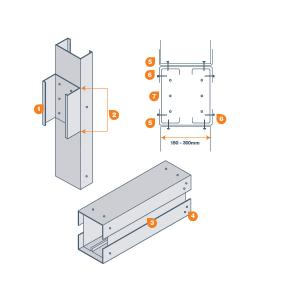

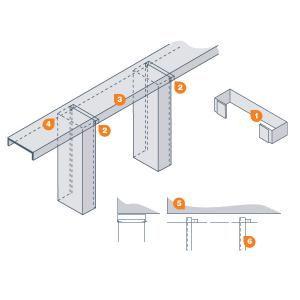

SFS Compound Lintel

- Short section - see design for No. of screws to jamb

- Equal to depth of back to back studs in lintel

- Stud sections to be cut short by flange depth of short section

- Fixings to be added after lintel is in position over short section

- Track

- Track (design may omit)

- 2 No. studs

- Indicates positions screws required at 300mm centres and maximum 150mm from each end

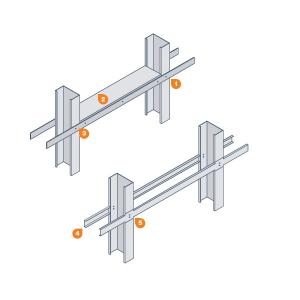

Compound member

- Top of stud to be kept below underside of track web

- Top of wrap-around track to be kept 25mm below bottom of track flang

- Deflection Bracket

- Top Track

- Track

- Track fixed to stud with screws at a maximum of 300mm centres at each flange

Compound member of Stud and Track

- Track section fixed to stud with screws at a maximum of 300 centres at each flange

- Base track

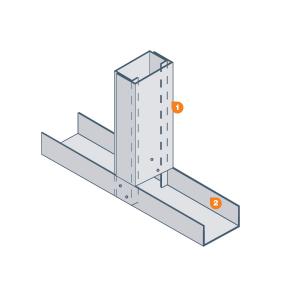

Track section Lintel

- Track

- Full height jamb stud

- Min 150mm section fixed with 4 No screws

- Track forming head to opening 2 No screws at each flange to stud

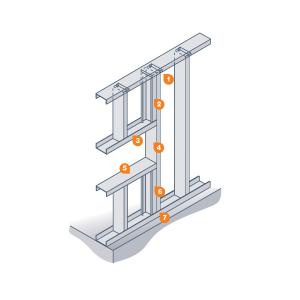

Blocking to Studs

- VB38 lateral bracing on both sides. Note - joints between straps are to be butted together and not lapped

- Solid blocking (of stud section) cut to fit tight between studs. Blocking typically every third bay but may be placed between every stud at teh request of design

- 1 No. screw at each stud and 3 No. per blocking piece each flange

- Bracing channel to be fixed both sides of panels tooling into stud

- At stud positions cut both flanges and flatten out. 2 No. screws to each stud

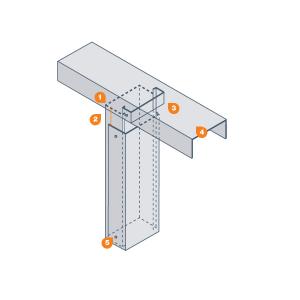

SFS Deflection Head type 3

- Deflection bracket

- Deflection bracket at every stud and fixed to track with 1 No. screws to each flan

- Deep runner track

- Stud must not be screwed to track. Top of stud 15 to 25mm below underside of track

- Top track fixed to concrete/hot rolled frame at 600 centres

- 15 - 25mm deflection gap between top of stud and underside of track

Double jamb with type 3 Deflection Head

- Deflection bracket attached to jamb stud qand cripple stud

- Cripple stud extends to head track. Fix to jamb stud with 2 No. screws at 300mm vertical centres

- Opening Lintel

- Jamb stud. Example here is single jamb however compound jambs can be used

- Opening Cill

- Jamb stud. Example here is single jamb however compound jambs can be used

- Cripple stud extends to base track. Fix to jamb stud with 2 No. screws at 300mm vertical centres

- Jamb stud and cripple stud both fixed to base track

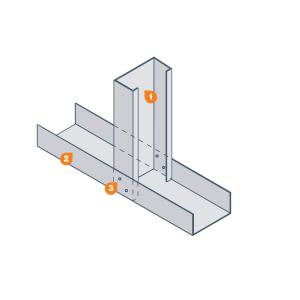

Stud Connection to Track 03

- Stud

- Tracks

- Typically 1 No screw for each flange for infill walling. Typically 2 No screws for each flange for SFS loadbearing walls

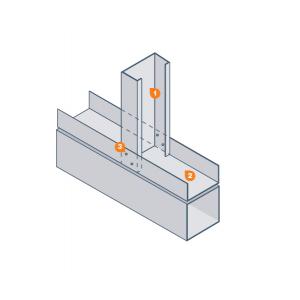

Stud Connection to Track

- Stud

- Track

- Typically 1 No screw for each flange for infill walling. Typically 2 No screws for each flange for SFS loadbearing walls

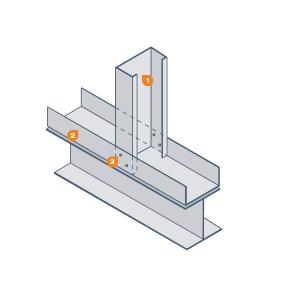

Stud Connection to Track 02

- Stud

- Track

- Typically 1 No screw for each flange for infill walling. Typically 2 No screws for each flange for SFS loadbearing walls